Careers

Ready for a career that rocks? We’re precisely what you’ve been looking for. Join the Tru-Stone team and start engineering your future today.

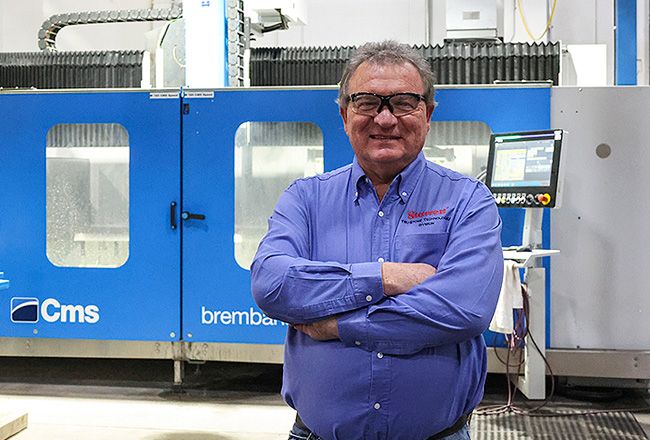

A TRULY GREAT TEAM

A Solid Place to Work

As a custom manufacturer of precision granite fixtures, the Tru-Stone team is filled with goal-oriented individuals who strive for excellence in all they do. Our on-the-job training and opportunities for career growth help ensure our employees are positioned for long-term success. If you’re a responsible professional with a can-do attitude and a strong attention to detail, there may be a place for you at Tru-Stone!

Beyond our comprehensive benefits package, Tru-Stone employees enjoy a work environment that prioritizes a healthy work-life balance. From our flexibility around family and school obligations to our ample career growth opportunities to our afternoon games of hacky sack, you’ll find fulfillment, financial stability and fun in your work at Tru-Stone.

Our Benefits

We strive to provide every opportunity for our employees to succeed both in and out of the workplace. Our benefits package features a variety of offerings and company-sponsored programs to help you get the most out of your career at Tru-Stone.

A Career to Talk About

WORK WITH US

Open Positions

Explore our open positions below and find the opportunity that’s right for you!