555-555-5555

mymail@mailservice.com

Technical Assistance

QUALITY COMES STANDARD

Top-Quality Capabilities

The quality and reliability of Tru-Stone products are direct results of our proven methods, top-quality workmanship and integration of high-quality parts. Our skilled team has the talent, expertise, and technical capabilities to craft outstanding parts that can serve as a component in or foundation of your design.

More information on the physical properties of different granite types can be found by checking out our

Spec Sheets.

Inserts

Inserts play a crucial role in the proper assembly of your stage, rails, clamps, etc. to the granite base. If even one insert pulls loose or has poor threads, your entire assembly is compromised.

To prevent insert degradation and rusting, Tru-Stone uses 300-series certified stainless steel inserts turned in our CNC turning centers and use proper thread gauges for quality control inspection. We turn a specially designed pattern on the outside diameter to maximize holding power of our proprietary mix of epoxy used to secure the inserts.

Minimum insert torque ratings from Federal Specification ASME B89.3.7:

Unified Threads

| Thread Size | Torque Rating |

|---|---|

| .250" | 7ft. lbs. |

| .3125" | 15ft. lbs. |

| .375" | 20ft. lbs. |

| .500" | 25ft. lbs. |

| .625" | 30ft. lbs. |

Metric Threads

| Thread Size | Torque Rating |

|---|---|

| M6 | 10 Nm |

| M8 | 20 Nm |

| M10 | 27 Nm |

| M12 | 34 Nm |

| M16 | 41 Nm |

Tru-Stone Standard Insert Sizes

| ANSI | Thread Depth (in.) | Insert Dia. (in.) | Insert Length (in.) |

|---|---|---|---|

| 4-40 | 0.280 | 0.500 | 1.250 |

| 6-32 | 0.345 | 0.625 | 1.250 |

| 8-32 | 0.410 | 0.625 | 1.250 |

| 10-32 | 0.475 | 0.625 | 1.250 |

| 1/4-20 | 0.625 | 0.625 | 1.250 |

| 5/16-18 | 0.781 | 0.625 | 1.250 |

| 3/8-16 | 0.938 | 0.625 | 1.250 |

| 1/2-13 | 1.250 | 0.750 | 2.000 |

| 5/8-11 | 1.550 | 1.000 | 2.250 |

| 3/4-10 | 1.875 | 1.250 | 3.000 |

| 1-8 | 2.500 | 1.250 | 3.000 |

| Metric | Thread Depth (mm) | Insert Dia. (in.) | Insert Length (in.) |

|---|---|---|---|

| M3 x 0.5 | 7.50 | 0.281 | 1.000 |

| M4 x 0.7 | 10.00 | 0.500 | 1.000 |

| M5 x 0.8 | 12.50 | 0.500 | 1.000 |

| M6 x 1 | 15.00 | 0.625 | 1.250 |

| M8 x 1.25 | 20.00 | 0.625 | 1.250 |

| M10 x 1.5 | 25.00 | 0.625 | 2.000 |

| M12 x 1.75 | 30.00 | 0.750 | 2.000 |

| M16 x 2 | 40.00 | 1.250 | 2.250 |

| M20 x 2.5 | 50.00 | 1.250 | 2.500 |

| M24 x 3 | 60.00 | 1.250 | 3.000 |

| Tapered | ||

|---|---|---|

| 1/8 NPT | 0.625 | 0.750 |

| 1/4 NPT | 0.750 | 1.250 |

| 3/8 NPT | 1.000 | 2.000 |

| 1/2 NPT | 1.250 | 2.000 |

| Solid Blank | ||

|---|---|---|

| Solid Blank | 0.500 | 1.250 |

| Solid Blank | 0.625 | 1.250 |

| Solid Blank | 0.750 | 2.000 |

| Solid Blank | 1.000 | 2.000 |

Holes

Tru-Stone can provide holes for location, clearance or weight reduction. Holes range from as small as .188” for air ports to large, wire-sawn holes for hubs or clearance.

If a hole must be placed near the edge of the granite, Tru-Stone’s designs implement the best practice of maintaining a wall thickness of at least the diameter of the hole between the hole and the edge.

STRAIGHT THRU-HOLE

COUNTERBORED HOLE

DOUBLE COUNTERBORED HOLE

Slots

T-slots are commonly incorporated into granite bases for flexibility in fastener location. T-slots are typically milled into steel bar stock and glued into the granite base. If required for your application, T-slots can also be milled into the granite itself.

COMMON SLOT

EMBEDDED STEEL SLOT

REPLACEABLE STEEL SLOT

SLOTS MILLED INTO GRANITE

SLOTS MILLED INTO GRANITE

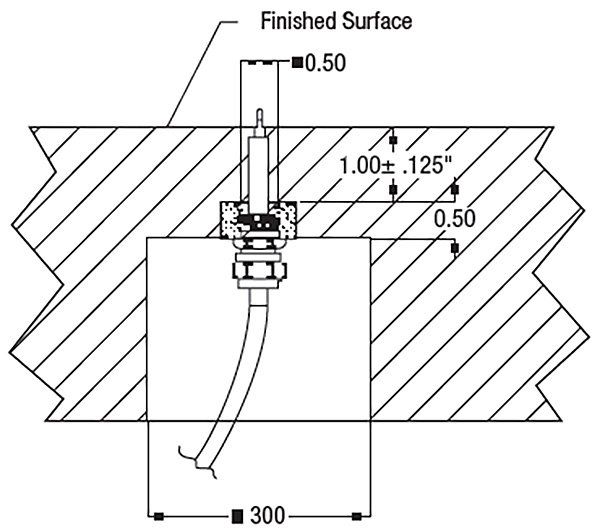

LVDT

Adapters for LVDT Transducer assemblies are available in our typical configuration shown here, or in a custom configuration to meet your application requirements.